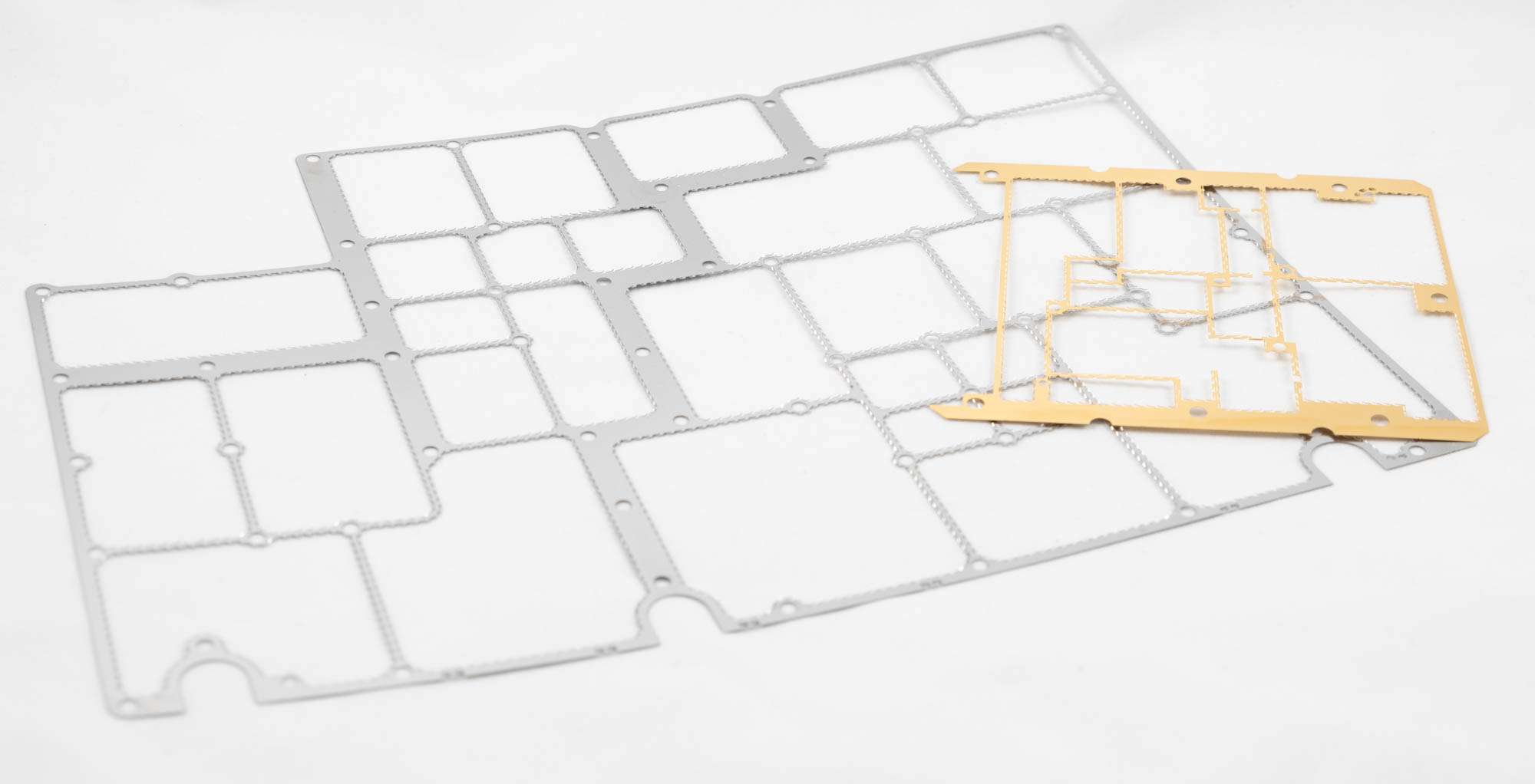

EMI Shielding Metallic Gaskets

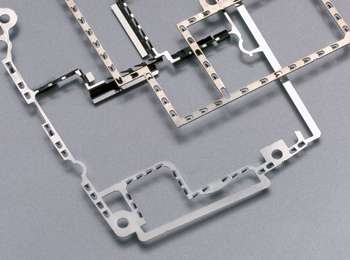

EMI shielding metallic gasket with low compression strength (spring teeth) for multi-cavities EMI shielding

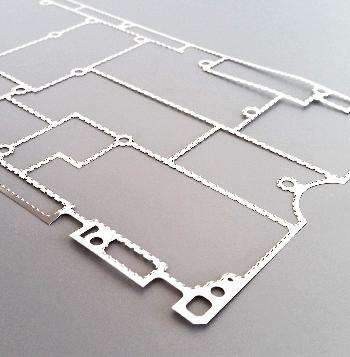

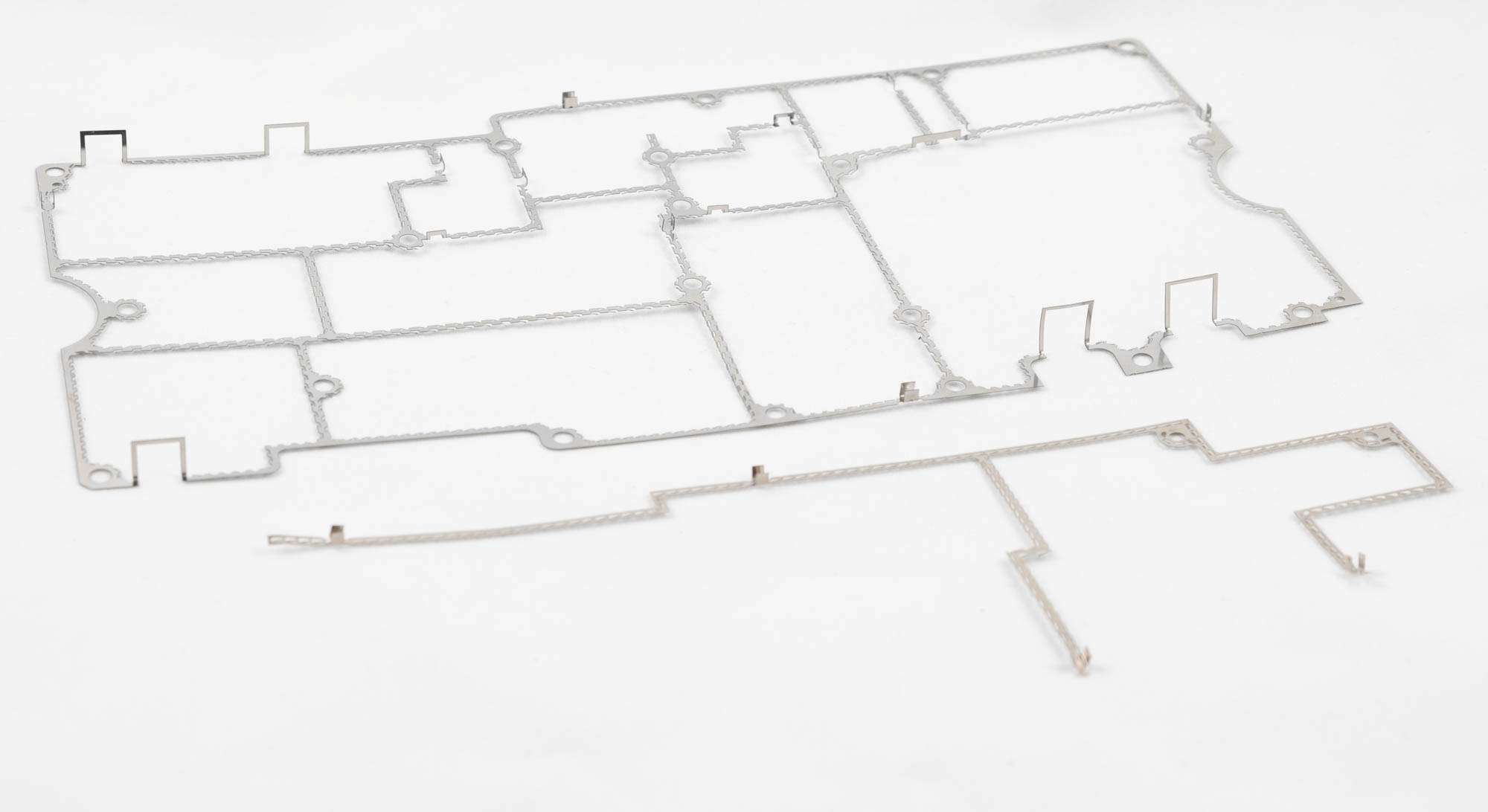

The EMI shielding metallic gaskets are chemically machined then the spring teeth are shaped along the entire length of the joint. This EMI shielding gasket is tailor-made and allows EMI sealing with low compression forces, also on multi-cavities.

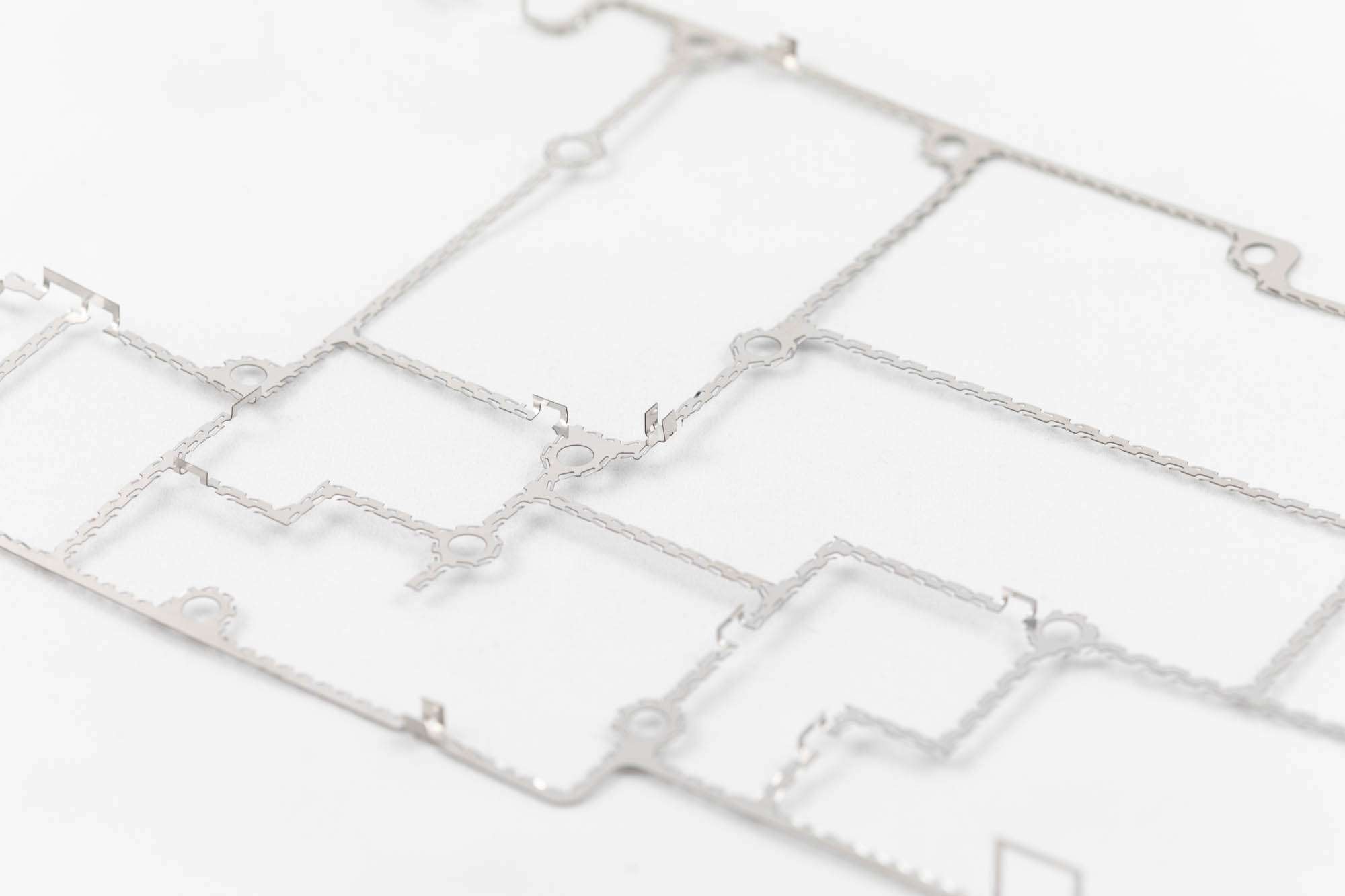

The spring teeth ensure grounding along the entire length of the EMI shielding metallic gasket. They guarantee total EMC sealing by compensating the mechanical gaps and spacing in the assembly.

EMI shielding metallic gaskets, key points:

- Excellent resistance to vibrating environments (aeronautics, military)

- Alternative to deposited silicone seals (lower compression forces)

- Installation made easier by shaping the joint

- Withstands several compression cycles (assembly/disassembly)

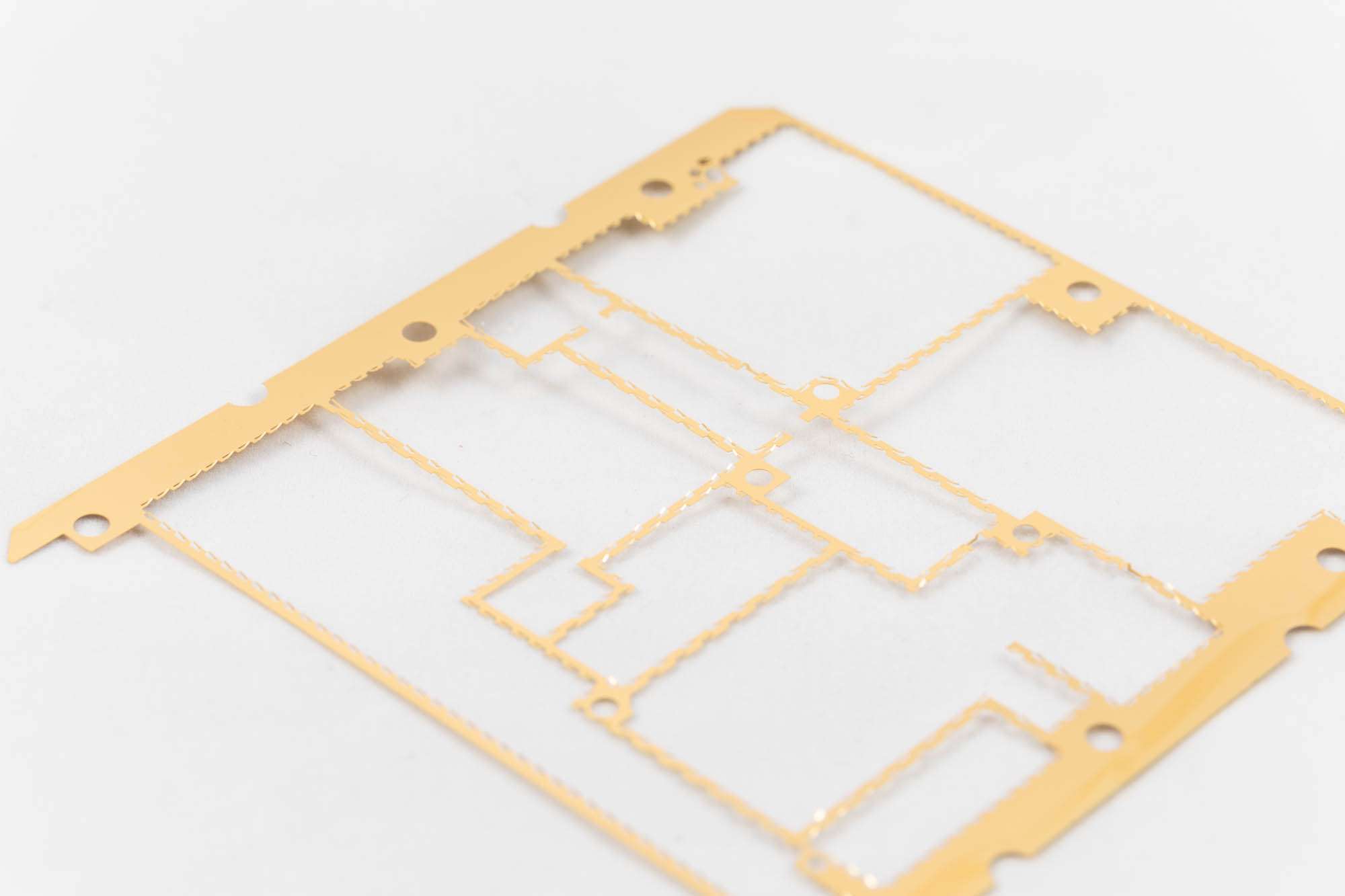

- Gold plating possible to increase conductivity

These EMI shielding metallic gaskets are custom made for each application.

Prototypes and samples of EMI metallic gaskets on request.

Description of EMI shielding metallic gaskets:

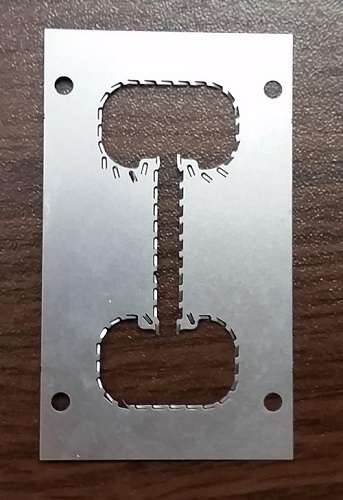

The EMI shielding metallic gaskets is obtained by chemical etching of a sheet of 0.15mm stainless steel (Sandvik Chromflex™ 7C27Mo2). Small spring teeth run along the joint to ensure spring contact between the two parts of the assembly.

The contact between the two boxes ensures the electromagnetic shielding function.

These EMI gaskets allow cavities to be isolated from each other with low compressive force, even on surfaces with high roughness or high tolerance level.

They are particularly suitable for telecoms type applications with multi-cavity housings (maximum dimensions 400 x 500mm).

EMI shielding metallic gaskets are designed to provide grounding on all point of the joint. Electrical contact is ensured by a series of spring teeth on all edges of the shielding joint.

The dimensions of the teeth are (approximately):

– Thickness 0.06mm

– Height 0.5mm

– Pitch 2.5mm.

We work based on your 2D plan of the joint location. We then do the work of modeling the spring teeth along the EMC shield joint. Then we submit it to you for validation.

The arrangement of the spring teeth is important to ensure grounding along the entire EMI metallic gaskets and thus ensure complete EMI shielding.

These metal EMC shielding gaskets are very adaptable and allow several cavities of equipment to be covered with a single gasket. The design and distribution of the spring-loaded teeth allows low compressive forces to be applied to the EMI shielding metallic gasket to ensure electrical contact.

These EMI shielding metallic gaskets are widely used as microwave shielding gaskets. This means that they are widely used on military and telecoms projects. Also on space assembly when outgassing is problematic.