An EMI shielding cap creates a Faraday cage around the component that emits parasitic frequencies.

PCB covers for EMI shielding are very well known. However, there are some specific features to bear in mind when choosing the part and the technology.

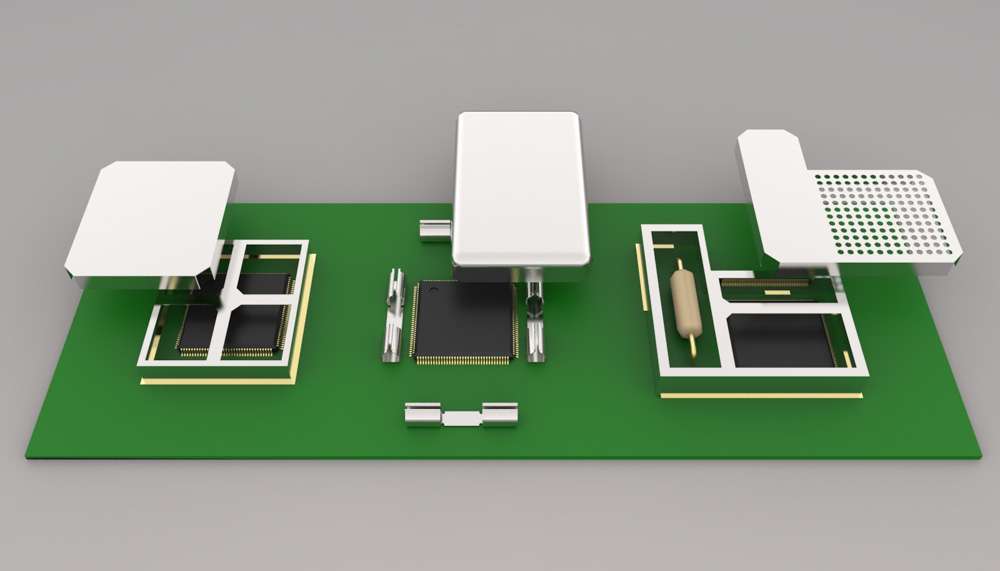

Composition of the EMI shielding solution :

Depending on the design constraints you have on your PCB, there are several solutions available to you:

- A single cover soldered directly to the PCB

- A belt soldered to the PCB to which the shielding cover is attached

- Clips soldered to the PCB to which the shielding cover is attached.

Clips for grounding the PCB have the advantage of limiting the buckling of parts and grounding specific points. However, EMI shielding belts can be designed as multi-cavities directly.

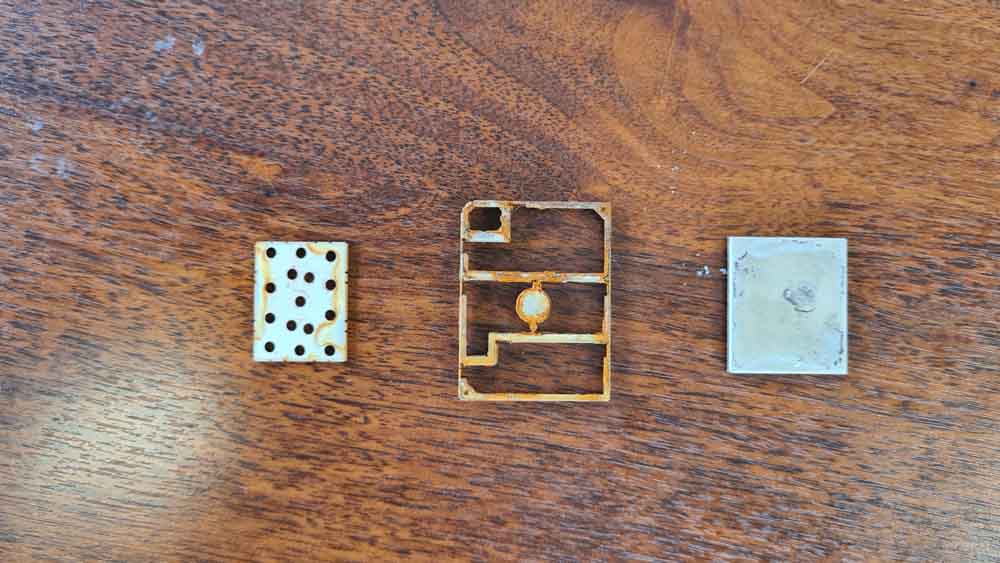

Materials for EMI shielding parts

These EMI shielding parts must have specific mechanical characteristics.

Against oxidation: The most commonly used material is stainless steel. However, tinning is often altered during shield shaping operations (cutting, stamping, bending, etc.).

The best alternative to these problems is Nickel Silver (made from Nickel, not steel). This material has intrinsic resistance to oxidation. This does not increase the risk of oxidation following shaping operations.

To ensure regular assembly and disassembly for the maintenance of the EMI shielding components, the alloy of the EMI shielding parts is adjusted to ensure sufficient flexibility and elasticity.

Alloys are adjusted according to the dimensions and functions of the EMI sheilding.

Manufacturing of EMI shielding parts

Most of this EMI shielding parts are custom made. Compelma realizes the tooling associated to the part and the quantities required. For prototyping or small quantities we use only soft tooling (lower cost than a standard tool but not adapted for mass production).

For automation (SMD – Surface Mounted Device) parts are designed with a tip on the top of the parts. this allows pick and place operation.

Packaging

To adapt the parts to automation (SMT), Compelma proposes different packaging as trays or reels. This packaging parts are also custom designed to fit every parts.