Fire-resistant thermal interfaces are specially designed materials that dissipate heat while providing protection against fire. These materials are already approved and used by major automotive industries. They are particularly useful in battery assemblies, especially for electric and hybrid vehicles. Thanks to their high resistance to flames and temperature, these materials are ideal for protecting batteries and busbars (components that carry high electric currents). At Compelma, we also offer these solutions. Our fire-resistant thermal interfaces can be cut and packaged according to the specifications of each project. More details are available in our article.

Introduction to Fire-Resistant Thermal Interfaces

Fire-resistant thermal interfaces are essential materials in many industrial applications. Their dual function of heat dissipation and fire protection makes them ideal components for ensuring the safety and performance of electronic and electrical systems.

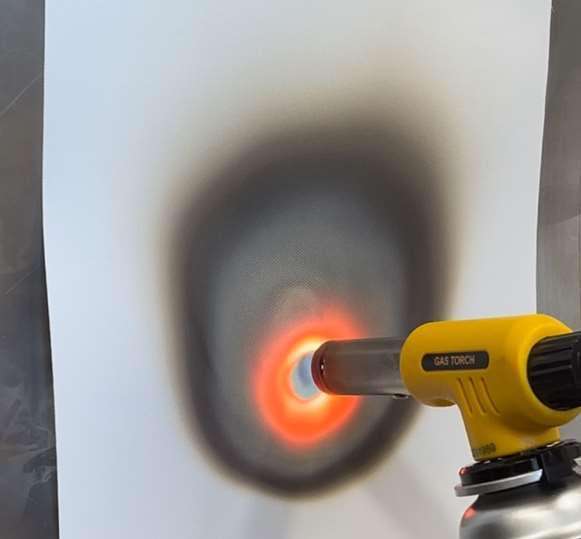

By efficiently dissipating heat, they prevent overheating that could damage equipment. Simultaneously, their ability to resist flames and prevent fire spread ensures effective protection in demanding installations.

Often, fire-resistant thermal interfaces contain silicone-based composites and various flame retardants. These elements are particularly valued for:

- Their high thermal resistance and flexibility, allowing them to adapt to different shapes and sizes of components.

- Their ability to limit flame propagation and maintain the integrity of components in the event of a fire.

Fire-Resistant Thermal Interface: For Which Applications?

Fire-resistant thermal interfaces are used in a multitude of industrial applications where thermal management and fire safety are paramount.

Aerospace and Defense

In the aerospace and defense industry, equipment reliability and safety are particularly important.

The electrical systems of fighter aircraft are subject to high temperatures due to the heat generated by the electronic equipment itself and the external environment. Fire-resistant thermal interfaces can then be employed to protect electronic components from high temperatures and fire risks.

Electronics and Telecommunications

Electronics and Telecommunications

Electronic and telecommunications equipment often generates a significant amount of heat, which can affect their performance and durability.

Data centers, for example, house thousands of servers and network equipment that generate significant heat during continuous operation. Thermal management and fire protection are mandatory to ensure the safety of operations.

Fire-resistant thermal interfaces can be used to dissipate this heat and prevent the overheating of sensitive components. They also provide a barrier against fire.

Automotive

In the automotive industry, fire-resistant thermal interfaces are widely used. They are heavily employed in the protection of batteries, engines, and vehicle electrical systems.

They are particularly useful in electric and hybrid vehicles, where heat management is essential. These materials protect batteries from fire risks and improve component durability by reducing operating temperatures.

Industrial Equipment

Industrial equipment (production machines, power distribution systems, etc.) often generates intense heat and is exposed to fire risks.

Fire-resistant thermal interfaces can then be used to manage this excessive heat and protect equipment from fires. In power plants, for example, these materials ensure safety and reliability by providing solid thermal management and fire protection.

The Advantages of Fire-Resistant Thermal Interfaces

Clearly, fire-resistant thermal interfaces offer many advantages. They:

- Maintain optimal operating temperatures of electronic components.

- Prevent overheating and thermal failures.

- Prevent flame propagation in the event of a thermal incident.

- Ensure the safety of equipment.

- Reduce the risks of failure in critical systems.

- Guarantee continuous operation of equipment under extreme conditions.

- Limit the thermal wear of electronic components.

- Reduce maintenance and replacement needs.

- Protect sensitive equipment and personnel against fire risks.

- Increase the overall safety of installations.

Customization and Industrial Integration of Fire-Resistant Thermal Interfaces with Compelma

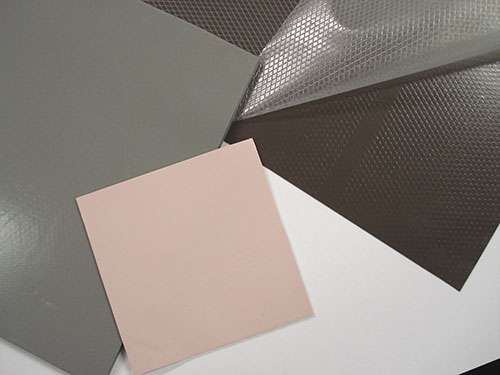

At Compelma, we understand that each industrial project has unique thermal management and fire protection needs. That is why we offer highly customizable fire-resistant thermal interfaces, designed to precisely meet the specific requirements of each project.

Our fire-resistant thermal interfaces can be cut and packaged according to the exact specifications of your projects. Whether you need complex shapes, specific sizes, or unique configurations, we have the capability to customize our materials to perfectly fit your applications.

This flexibility not only ensures optimal integration into your systems but also maximizes efficiency in terms of thermal dissipation and fire protection.

The fire-resistant thermal interfaces offered by Compelma are designed for a wide range of industries, including aerospace, automotive, electronics, and telecommunications.

Do you want to learn more about our fire-resistant thermal interfaces? Do you have a specific project but are not sure which type of thermal interface to choose? Our team of experts is available to answer your questions and assist you at every step of your project. Feel free to contact us!