Thermal dissipation is the process through which the heat generated by a system (or device) is removed to maintain an optimal operating temperature. This process is crucial in industrial applications as it prevents overheating and ensures the reliability of equipment. Currently, various thermal dissipation solutions are available in the market. Heat sinks, fans, and cold plates are commonly used to manage heat in numerous sectors such as electronics, automotive, and manufacturing. Explore more in our detailed article.

Thermal Dissipation: Definition

Thermal dissipation is the process by which a system or device eliminates the heat generated during its operation to maintain a stable temperature and avoid overheating.

Thermal dissipation can occur through several mechanisms:

- Thermal Conduction: This is the transfer of heat through a solid, liquid, or gaseous material. For example, when one end of a metal bar is heated and the warmth spreads gradually to the other, it illustrates thermal conduction.

- Thermal Convection: This involves the transfer of heat via fluid movement (liquids or gases). When hot air rises and cold air descends in a room, heat transfer occurs through convection.

This thermal dissipation is crucial for the proper functioning and longevity of electronic components, machines, engines, and systems that generate heat during use.

Common cooling methods include:

- Heat Sinks and Fans: To cool processors, graphics cards, etc.

- Coolants in the Automotive Industry: For maximum safety.

- Cooling Systems in Data Centers: To prevent failures.

- Heat Sinks and Fans for Mobile Devices: To maintain performance in smartphones, laptops, and gaming consoles.

The Importance of Thermal Dissipation in Industrial Applications

Failure Prevention:

Overheating is a primary cause of electronic and mechanical component failures. If the heat generated by a device isn’t properly dissipated, the internal temperature rises. This can result in:

- Melting or deformation of components, potentially causing short circuits.

- Degradation of materials, compromising component integrity.

- Component failures.

Performance Improvement:

Electronic device performance often correlates with their ability to stay at an optimal temperature. Processors, for instance, might reduce their clock speed to prevent overheating, which decreases performance. Effective cooling sustains high processing speeds and prevents temperature fluctuations that can cause operational errors.

Increased Device Longevity:

Component lifespan is significantly affected by operating temperatures. Heating and cooling cycles can lead to material fatigue, cracks, or deformations over time. High temperatures also accelerate oxidation, corroding metallic components and shortening their lifespan.

Enhanced Safety:

Heat management is also a safety concern. Excessive overheating can cause fires, especially where flammable materials are involved. Thermal dissipation systems help protect users and operators from high-temperature risks.

Better Energy Efficiency:

A well-cooled system is more energy-efficient. Undissipated heat constitutes a significant energy loss. Efficient thermal management can reduce these losses.

Thermal Dissipation Solutions

Heat Sinks:

Passive devices designed to remove heat from a component to the surrounding air. Made from materials with high thermal conductivity like aluminum or copper, heat sinks are easy to install and use. However, they might not suffice for high-power components and may need to be combined with fans or liquid cooling systems.

Thermal Interfaces:

Materials like thermal paste and pads that improve thermal conductivity between a component and a heat sink by filling microscopic irregularities in contact surfaces. They reduce thermal resistance and are easy to apply and replace, although some pastes may degrade over time.

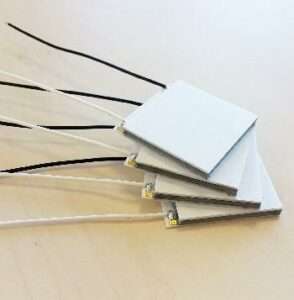

Peltier Modules:

These utilize the thermoelectric effect to move heat from one side of the module to the other when an electric current is applied. They can provide cooling below ambient temperatures and offer precise temperature control, yet may be energy-inefficient and require additional heat dissipation devices.

Cold Plates:

Cooling devices using fluids to remove heat from components. The fluid circulates through built-in channels, absorbing heat and moving it to a distant radiator or heat exchanger. They are very effective for large heat quantities, especially where space is limited, but require regular maintenance to prevent leaks or clogs.

Each thermal dissipation solution has its advantages and limitations, and the right choice depends on the system’s cooling needs, thermal power to be dissipated, space constraints, budget, etc. Need advice on this topic? Feel free to contact Compelma for personalized guidance.