Thermal management and dissipation in electronics

All the technologies to keep the electrical products at the right working temperature

Each of our product for thermal management can be customised to perfectly fit your need and specifications.

Custom Heat Sinks | Cold Plates | Thermal Interfaces | Thermo Electric Modules

Custom Heat Sinks

Custom heat sinks dissipate heat from electronic equipment by conduction, radiation and convection.

These energy transfers can be improved by fans, thermoelectric modules, cold plates, etc.

These heat sinks can be extruded then machined, from custom or standard profiles.

Compelma also offers interfacing with high performance thermal interfaces to increase thermal transfer.

Thermal Interface Materials (TIM)

Thermal interface materials (TIM) eliminate the air gaps (insulators) that exist between the heat sinks and the heating components.

Without a thermal interface, thermal transfer quickly plateaus and power components can fail or degrade.

Standard thermal interface materials (TIM) go up to 17W/m.K and are available in several hardnesses and thicknesses.

We support you in choosing the thermal interface for your project.

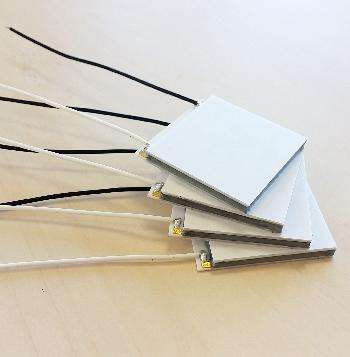

Thermo Electric Module

Thermo electric modules are using Peltier effect to create a temperature differential between the two faces (by passing an electric current through the thermocouples of the module).

These thermo electric modules allow precise and rapid temperature control by modulating the current. These Peltier modules can be used in active or passive mode.

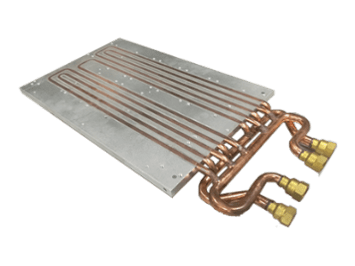

Cold Plates

Cold plates allow calories to be drained outside of equipment via a fluid passing through a tube (or directly through the cold plate for FSW cold plates).

Heat transfer and efficiency are increased by laminating the tube in a metal plate (or directly machined if made by FSW technology).

Several materials are available. Designs are custom made.