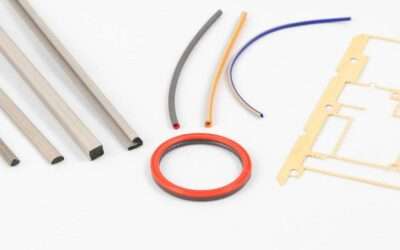

Why use an EMI and/or IP gasket in an electrical assembly? The primary aim is to ensure a seal against :- To particles (dust)- And/or fluids (air, water)- And/or electronics (grounding) in the case of EMI (electromagnetic compatibility) shielding joints.This water...

Blog

Consult our technical articles “for dummies”

Everything you need to know about the different EMI and Thermal products

Spring Finger Contacts For Dummies

What is a Spring Finger Contact? A spring finger contact (SMT) is a small mechanical part used to make connection or grounding on electronic projects. These SMT contacts are made to support harsh environment (humidity, temperature, and vibrations). Spring finger...

The what, why and how of elastomeric connectors

Micro-electronic assembly always needs more connection density on reduced spaces.Therefore electronic connections are done by smaller and denser connectors. That for those assemblies that elastomeric connectors has been designed. Elastomeric connectors ensure high...

EMI shielding film for EMI/RF window

How to make a transparent, conductive surface for EMI & RF shielding applications? EMI shielding film for EMI/RF window is a transparent EMI shielding film, photo-etched from a copper sheet. This EMI shielding film is laminated to make EMI shielding windows. We...

How to choose a Gap Filler or thermal pad

What is a Thermal Interface Material (TIM) a.k.a. gap filler? A gap filler, as its name suggests,allows to fill the existing gaps in electronical assemblies in order to increase the thermal drain.Air indeed has a very low thermal conductivity (0,025 W/m·K), which...

PCB covers for EMI Shielding

An EMI shielding cap creates a Faraday cage around the component that emits parasitic frequencies. PCB covers for EMI shielding are very well known. However, there are some specific features to bear in mind when choosing the part and the technology. Composition of the...