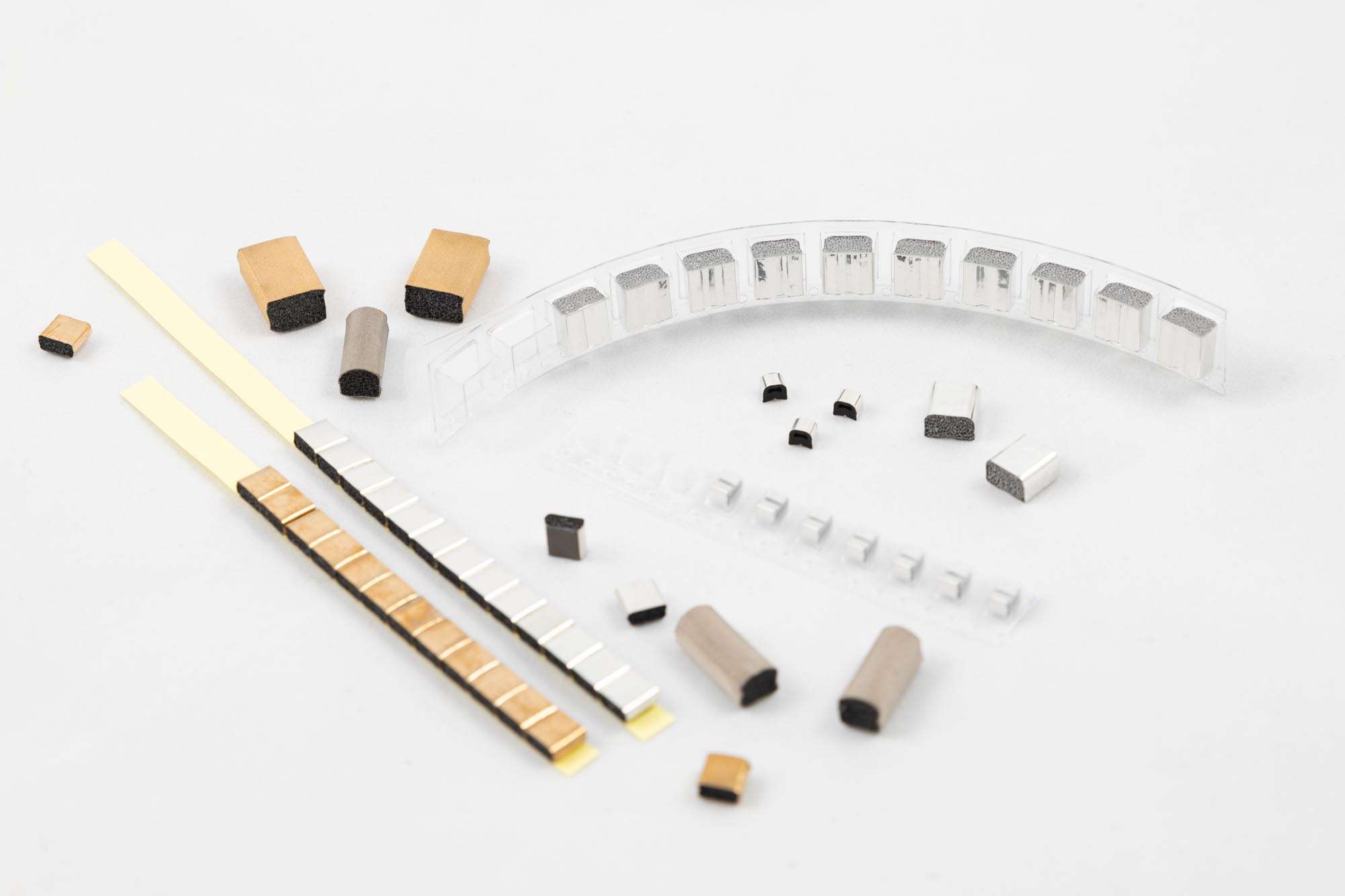

Conductive Fabric over Foam (FoF) gaskets

F-o-F EMI shielding gaskets are the most common solution for standard electromagnetic and RF sealing of equipment

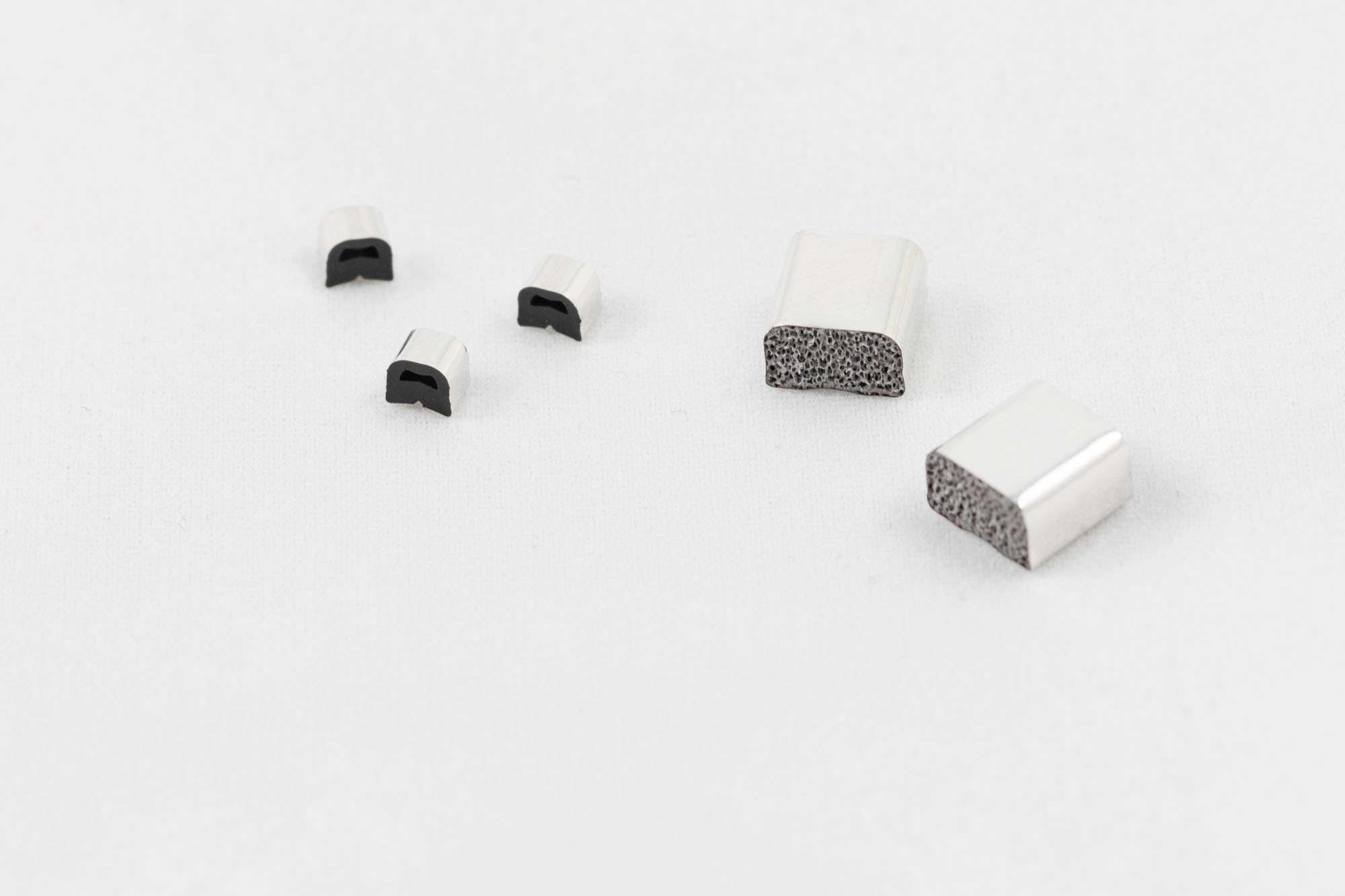

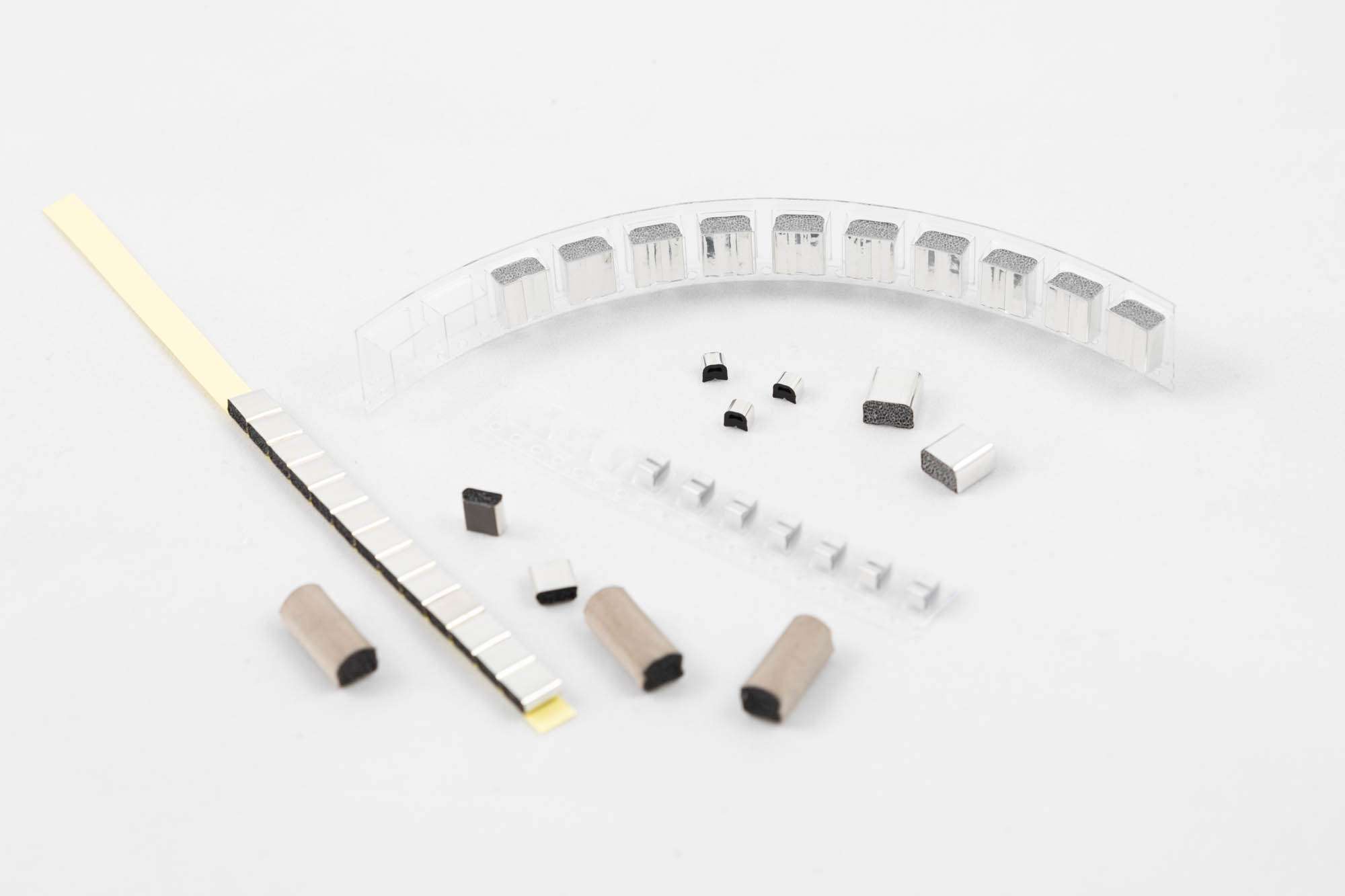

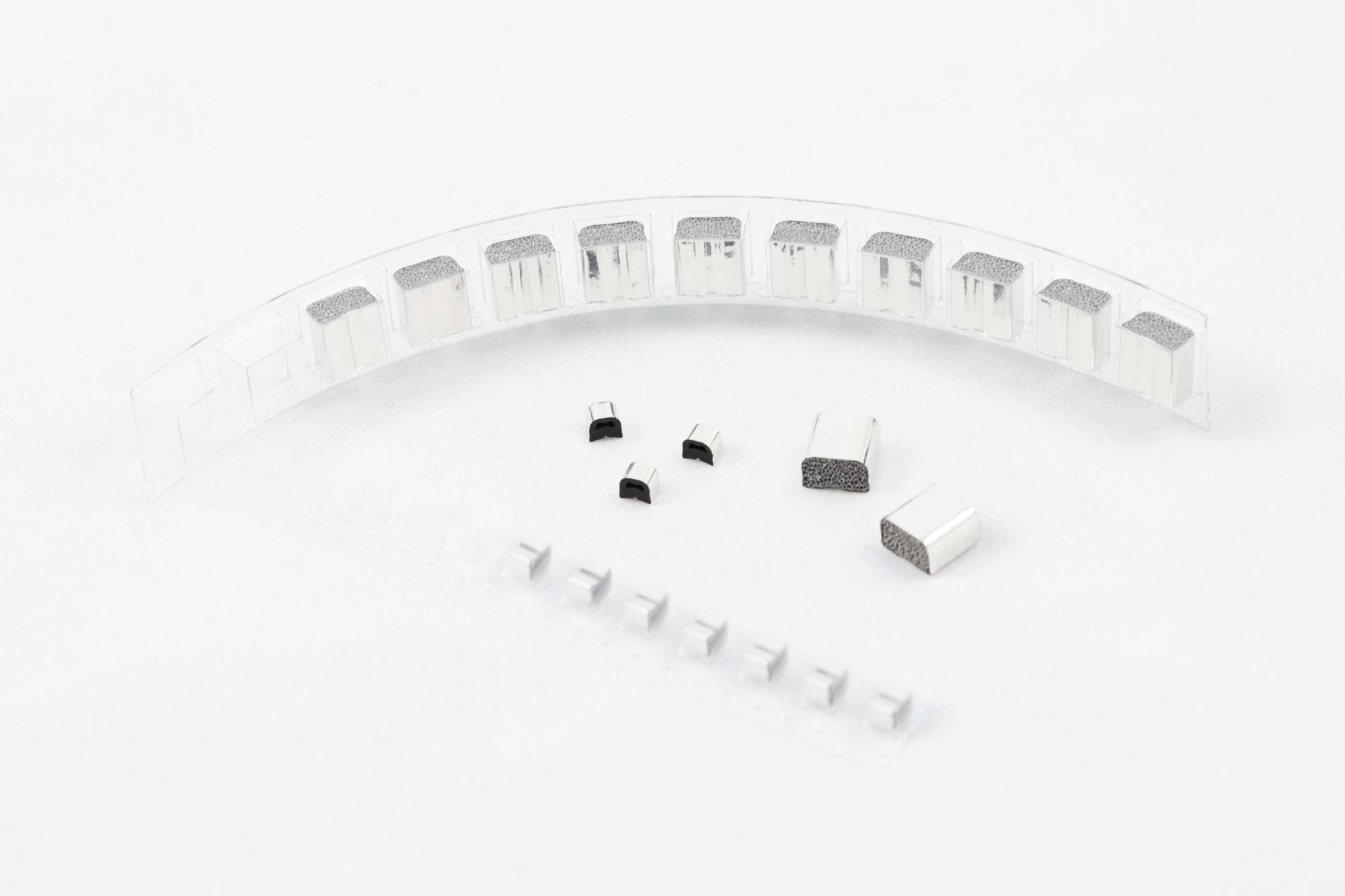

These conductive joints are made from a polyurethane foam profile around which a conductive (metallic) fabric is thermoformed. Electrical conductivity is thus ensured over the entire exterior surface of the EMC shielding joint. The structure of the fabric ensures good resistance to abrasion.

The body of the joint is made of polyurethane foam. This structure allows very low compression forces and good mechanical strength even after several compression cycles (>800,000 cycles).

Think about it: Flat profiles can be cut to make connector EMI shieldings.

Conductive fabric over foam (FoF) gaskets, Key points :

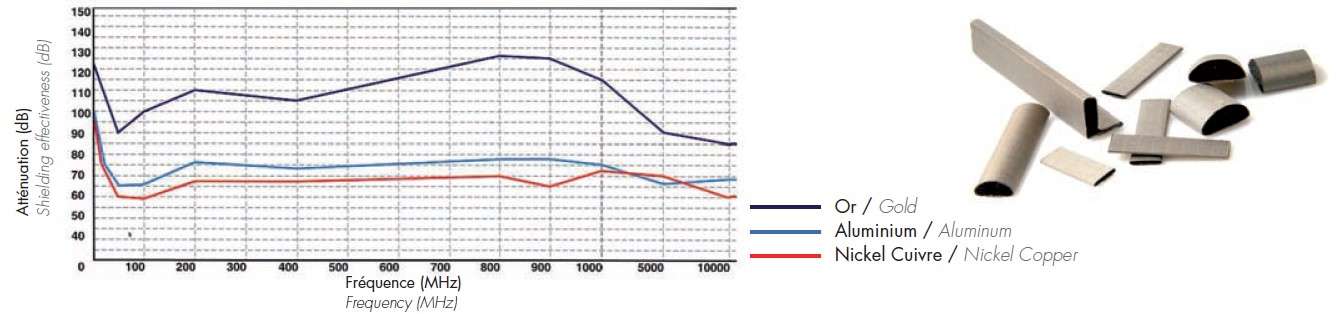

- Shielding level greater than 60dB (from 30MHz to 1GHz) – MIL-Std-285

- Adhesive assembly (conductive or partial non-conductive)

- Low compression force and abrasion resistance

- Cut to length, can be delivered in SMT pads

- UL94-V0, RoHS and Halogen-free

- Depending on the profile, the compression level is 30% to 70%

Large catalog of standard profiles of conductive fabric over foam gaskets available, cut to length on request.

Prototypes and samples on request, depending on availability.

Learn more about conductive fabric over foam (FoF) gaskets

These conductive fabric over foam (FoF) gaskets are economical and easily applicable in the majority of electronic projects. Conductivity is ensured over the entire periphery of the joint by the conductive fabric. The metallization (Ni/Cu/Ni) applied to the polyester fabric guarantees very good abrasion resistance (in the case of EMI shielding on a door opening for example). The polyurethane foam body ensures good mechanical behavior and good resilience.

These soft EMI shielding gaskets are widely used for electromagnetic sealing of equipment. Due to their low costs and ease of use.

The wide range of profiles and dimensions allows adaptation to all projects. If you do not have demanding technical constraints (high fluid tightness, strong mechanical constraints) these EMI seals are preferred.

These conductive fabric over foam (FoF) gaskets can be delivered with a conductive adhesive or a non-conductive partial adhesive for better adhesion.

These EMI shielding gaskets can be cut to size (holes for screws, beveling for assembly, etc.).

All our EMI foam gasket references are UL94-V0 certified.

The operating range is -20°C to +100°C.

Attenuation is 60dB to 100dB from 30MHz to 1GHz. Complying with MIL-Std-285 standard.

A project, a request?

Catalog of our conductive fabric over foam (FoF) gaskets

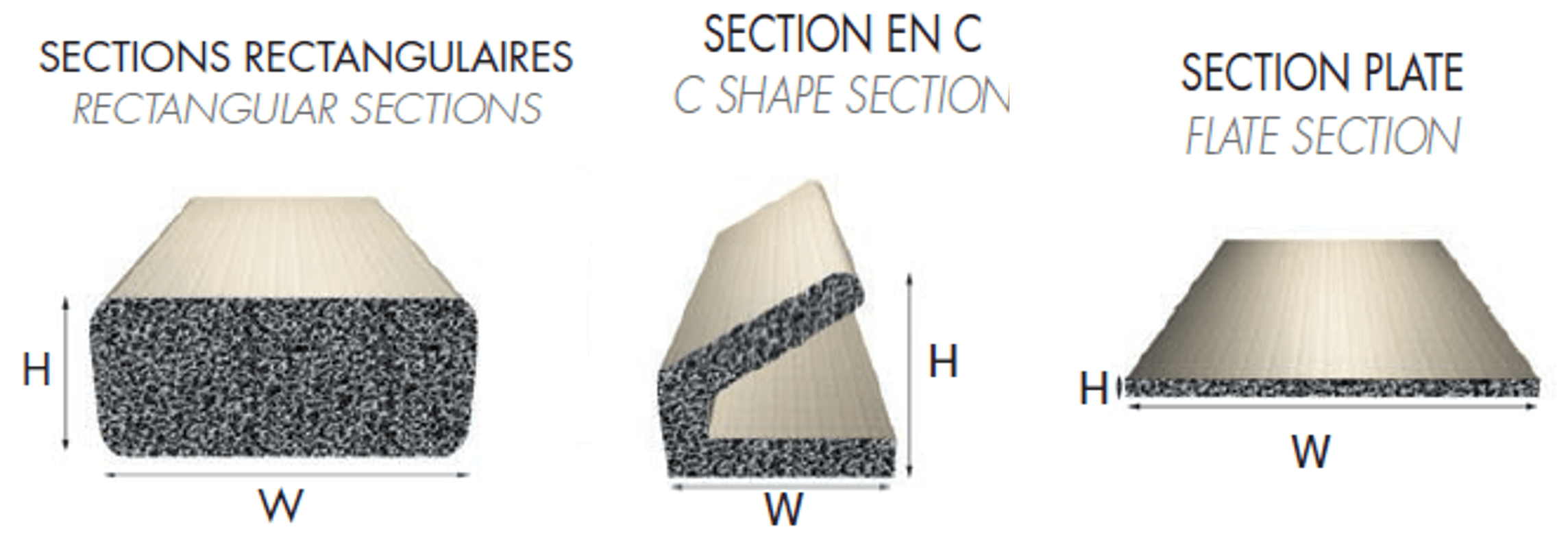

The catalog below lists the main existing dimensions and profiles.

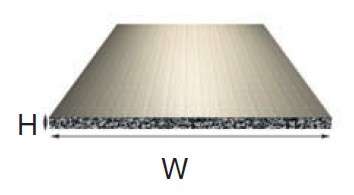

Flat profile

| Height (mm) | Width (mm) | Adhesive width (mm) |

| 0,5 | 5,0 | 3,0 |

| 0,5 | 7,0 | 4,0 |

| 0,5 | 10,0 | 5,0 |

| 0,5 | 13,0 | 6,0 |

| 0,7 | 3,0 | 2,0 |

| 0,9 | 4,0 | 2,0 |

| 1,0 | 5,0 | 3,0 |

| 1,0 | 6,0 | 3,0 |

| 1,0 | 7,0 | 4,0 |

| 1,0 | 9,0 | 4,0 |

| 1,0 | 8,0 | 4,0 |

| 1,0 | 10,0 | 5,0 |

| 1,0 | 12,0 | 6,0 |

| 1,0 | 13,0 | 6,0 |

| 1,0 | 18,0 | 3,0×2 |

| 1,0 | 25,4 | 3,0×2 |

| 1,2 | 4,0 | 2,0 |

| 1,2 | 7,0 | 4,0 |

| 1,2 | 5,0 | 3,0 |

| 1,2 | 10,0 | 5,0 |

| 1,5 | 5,0 | 3,0 |

| 1,5 | 7,0 | 4,0 |

| 1,5 | 6,0 | 3,0 |

| 1,5 | 13,0 | 6,0 |

| 1,5 | 50,8 | 3,0×2 |

| 1,5 | 25,4 | 3,0×2 |

| 1,6 | 7,6 | 4,0 |

| 1,8 | 7,0 | 4,0 |

| 1,8 | 5,0 | 3,0 |

| 1,8 | 10,0 | 5,0 |

| 2,0 | 20,0 | 3,0×2 |

| 2,0 | 27,0 | 3,0×2 |

| 2,0 | 21,0 | 3,0×2 |

| 2,0 | 41,3 | 3,0×2 |

| 2,0 | 28,6 | 3,0×2 |

| 2,0 | 45,0 | 3,0×2 |

| 2,0 | 60,0 | 3,0×2 |

| 2,3 | 19,1 | 3,0×2 |

| 2,5 | 21,0 | 3,0×2 |

| 2,5 | 55,0 | 3,0×2 |

| 2,5 | 43,0 | 3,0×2 |

| 3,0 | 25,4 | 3,0×2 |

| 3,2 | 40,0 | 3,0×2 |

| 3,7 | 21,0 | 3,0×2 |

| 4,6 | 41,3 | 3,0×2 |

Rectangular profile

| Height (mm) | Width (mm) | Adhesive width (mm) |

| 2,0 | 3,0 | 2,0 |

| 2,0 | 6,0 | 3,0 |

| 2,0 | 4,0 | 2,0 |

| 2,0 | 9,5 | 4,0 |

| 2,0 | 7,0 | 3,0 |

| 2,0 | 10,0 | 5,0 |

| 2,0 | 12,0 | 6,0 |

| 2,0 | 15,0 | 7,0 |

| 2,0 | 21,0 | 10,0 |

| 3,0 | 3,0 | 2,0 |

| 3,0 | 3,9 | 2,0 |

| 3,0 | 4,0 | 2,0 |

| 3,0 | 7,0 | 3,0 |

| 3,0 | 6,0 | 3,0 |

| 3,0 | 9,0 | 4,0 |

| 3,0 | 10,0 | 5,0 |

| 3,0 | 13,0 | 7,0 |

| 3,0 | 12,0 | 6,0 |

| 4,0 | 4,0 | 2,0 |

| 4,0 | 6,0 | 3,0 |

| 4,0 | 5,0 | 3,0 |

| 4,0 | 8,0 | 4,0 |

| 4,0 | 7,0 | 3,0 |

| 4,0 | 14,5 | 7,0 |

| 4,0 | 10,0 | 5,0 |

| 4,0 | 15,0 | 7,0 |

| 5,0 | 5,5 | 3,0 |

| 5,0 | 5,0 | 3,0 |

| 5,0 | 6,0 | 3,0 |

| 5,0 | 8,0 | 4,0 |

| 5,0 | 7,0 | 3,0 |

| 5,0 | 10,0 | 5,0 |

| 6,0 | 6,0 | 3,0 |

| 6,0 | 10,0 | 5,0 |

| 6,0 | 13,0 | 7,0 |

| 7,5 | 15,0 | 7,0 |

| 8,0 | 6,0 | 3,0 |

| 8,0 | 13,0 | 7,0 |

| 8,0 | 10,0 | 5,0 |

| 9,5 | 9,5 | 4,0 |

| 9,5 | 12,7 | 6,0 |

| 9,5 | 25,4 | 12,0 |

| 10,0 | 10,0 | 5,0 |

| 10,0 | 18,0 | 9,0 |

| 12,0 | 8,0 | 4,0 |

| 12,0 | 12,0 | 6,0 |

| 13,0 | 10,0 | 5,0 |

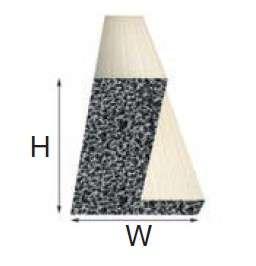

C Section Profile

| Height (mm) | Width (mm) | Adhesive width (mm) |

| 3,5 | 7,5 | 3,0 |

| 6,4 | 5,9 | 3,0 |

| 8,0 | 8,0 | 4,0 |

| 9,8 | 10,7 | 6,0 |

| 10,0 | 10,0 | 5,0 |

| 11,9 | 12,4 | 6,0 |

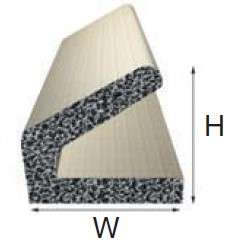

L Section Profile

| Height (mm) | Width (mm) | Adhesive width (mm) |

| 11,0 | 11,0 | 6,0 |