How to make a transparent, conductive surface for EMI & RF shielding applications?

EMI shielding film for EMI/RF window is a transparent EMI shielding film, photo-etched from a copper sheet. This EMI shielding film is laminated to make EMI shielding windows. We get a copper-wire mesh laminated on a PET sheet, with optical adhesive.

The transparent EMI shielding film can then be laminated on windows or various surfaces (glass, polycarbonate, PET) and insures a high electrical conductivity overall the surface.

What are the applications of EMI film (copper micro-mesh) for EMI shielding?

Here are 6 examples!

Transparent EMC/EMI shielding film on EMI window for a connected fridge (RFID) or automatic inventory cabinet

The transparent EMI shielding film is laminated onto the EMI window, insuring electromagnetic and radio-frequency-proofing within the fridge or the cabinet. Ground contact is made directly onto the film, against the frame. EMI shielding gasket can also be used to compensate mechanical gaps when assembling.

Electromagnetic and radio-frequency waves are reflected and conducted onto the film surface, and then conducted to the grounded frame.

EMI shielding (RFID) for connected dispensers, fridges or cabinets

Transparent EMI/RF shielding film for EMI windows on meeting room for confidentiality

EMI and RF shielding film ensures a global phone or Wi-Fi waves’ proofing (shielding>40dB for frequencies from 10MHz to 10GHz). The room is thus completely sealed from electromagnetic and radio frequency waves, while allowing light to come in thanks to its transparency (>81% for visible light).

The EMI shielding film is also infrared-proofed, protecting the room from thermal cameras.

The micro copper-mesh film can also be used for bigger projects, as to cover openings in buildings (windows or big glass surfaces) for example.

RF and EMC shielding for a confidential meeting room

Transparent EMI shielding film for the safety EMI window of medical equipment (CE certified)

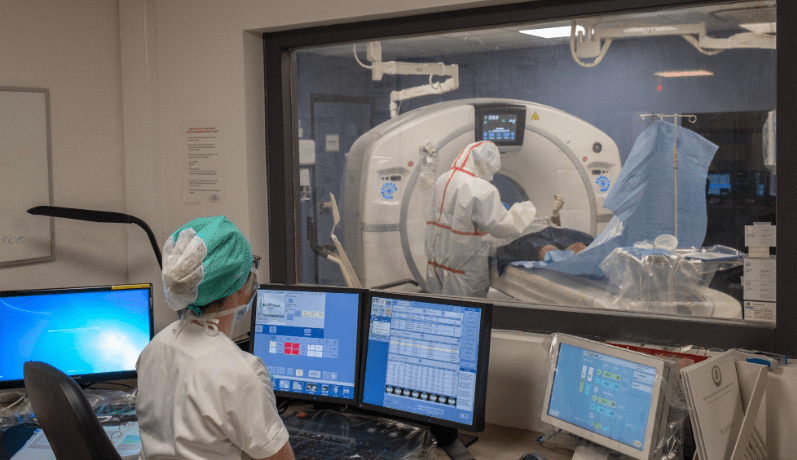

The conductive EMI film allows medical devices to be EMI-proofed. Medical monitors screen can thus be shielded so that they don’t radiate electromagnetic interferences within the room. Patient security and surrounding devices reliability is thus ensured.

This EMI shielding film is also used to protect staff during medical imaging operations.Indeed, composed of a micro copper mesh, the film is de facto electromagnetic waves proofed (such as X-ray).

Electromagnetic shielding of a window in a medical imaging room

Transparent EMI shielding film for EMI window on anechoic chambers (for the tests and EMI qualifications, to be CE compliant)

The EMI shielding film (Cu Mesh) allows the anechoic chambers’ openings to be perfectly EMI and RF-proofed. It completes the anechoic chamber by allowing the inside of the room to be visible from the outside, without inside or outside pollution.

Anechoic chamber for EMC qualifications

EMI shielding windows for on-field military equipment’s protection

On-field military forces can be detected thanks to radio-frequencies or electromagnetic emissions. Equipment brought on the field can radiate such EMI waves. For the forces to be invisible, the equipment have to be perfectly EMI-proofed.

The EMI shielding film is laminated onto screens or armored vehicles’ windows. With its high conductivity, it ensures the EMI and RF shielding of all openings, while ensuring a high transparency for the staff.

The EMI shielding film is also infrared-proofed, making equipment totally invisible from thermal cameras while keeping its permeability to the visible spectrum waves.

Electromagnetic shielding (EMC) of a screen on on-board military equipment

Transparent EMI shielding film for electromagnetic certification of display screens

This EMI shielding film is an invaluable ally in the EMC standards certification stages for CE certification. It provides a complete seal against electromagnetic waves (EM) and radio frequencies (RF) while ensuring permeability in the visible spectrum (>81%).

This is why this shielding film is widely used for shielding signalling equipment and digital displays.

Electromagnetic shielding (EMC) for a display screen

Microscopic view of the copper mesh of the EMC shielding film (Cu Mesh)

How does this anti radiofrequency (RF) and electromagnetic (EMC) wave film work?

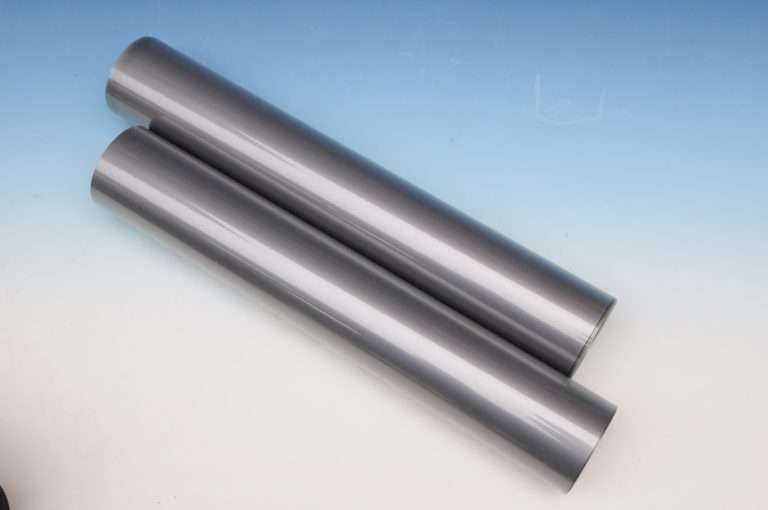

The manufacturing process for this EMI shielding film is fairly straight forward. The copper film is laminated onto a PET backing. The assembly is then photo-machined to remove the material in precise, regular locations. The result is a microscopic copper mesh (copper wire width: 21μm, copper mesh size: 255μm).

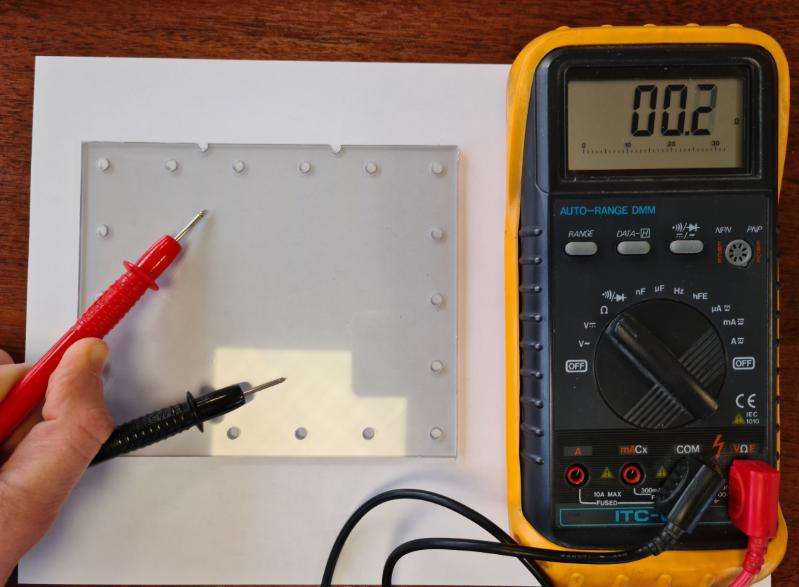

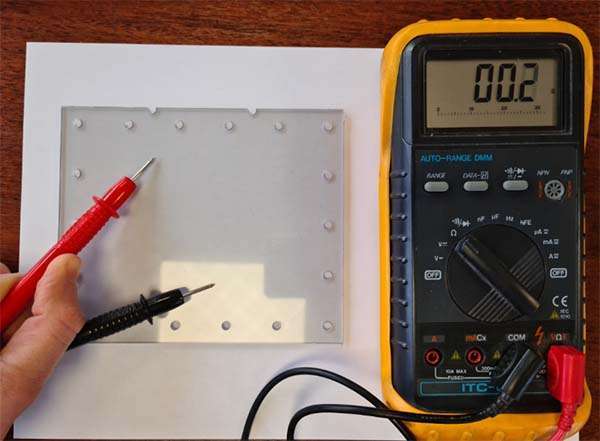

The electrical surface resistance in surface of the EMI film is around 0.1Ω/square. This very low surface resistance is a direct result of the raw material used: raw copper.

The resulting shielding film is laminated with an optical adhesive, then with protective liners on both sides. The copper surface is also treated to ensure that it does not oxidise over time.

This Cu Mesh EMI shielding film (for the MFHP reference) is manufactured in rolls 1,500mm wide. It can then be manufactured in lengths of several dozen metres or even hundreds. The roll of material can then be cut in width and length to deliver the most suitable film formats for your application.

EMC shielding film: Microscopic photo-minished copper mesh

What is the difference with ITO-based EMI shielding film?

The oldest technology for transparent electromagnetic shielding is ITO (Indium Tin Oxide). These are metal particles that are sprayed onto a PET surface in a very thin layer. These particles provide conductivity on the surface of the film.

These ITO shielding films have several disadvantages:

– The resistivity is very high compared with a copper mesh: >10 Ohms/square.

– Oxidation resistance is very low. After a few years, the ITO film yellows and/or retains fingerprints. This phenomenon is due to the oxidation of the projected metal particles.

– The quality of ITO films is extremely variable. Depending on the particles used and the manufacturing process, the quality and price vary greatly without guaranteeing excellent results over time.

– Mechanical strength is less good with ITO film. This type of film is more likely to scratch or break during handling or application. This has a direct impact on the quality of the resulting EMC shielding.

For these reasons, several studies show that the market for metal micro-mesh film is set to grow, while the ITO market is shrinking.

How do I know if this transparent EMI shielding film can be used for EMI windows on my electromagnetic shielding project?

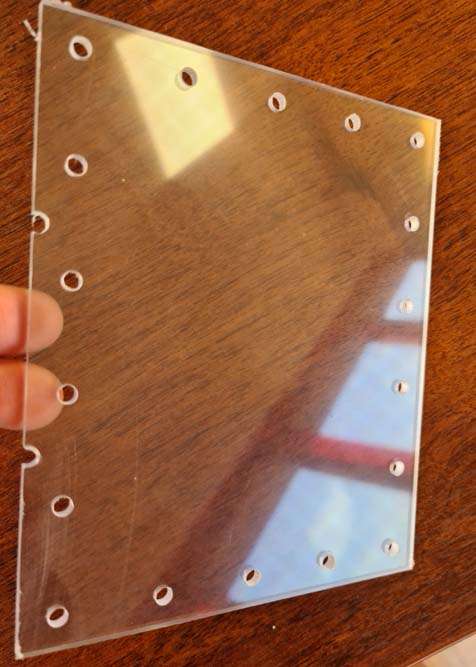

We have several samples available of EMI windows (A4 or larger) which we can send you within 24 to 48 hours. To take advantage of this, send us a message via the chat (bottom right) or via the contact form at the bottom of the page.

Go to the technical specifications of the transparent EMC shielding film (Cu Mesh) by clicking to the below button.

EMC shielding film: Microscopic photo-minished copper mesh