Characteristics of Spring Finger Contacts SMD

Spring finger contacts SMD (Surface Mount Technology) are essential for creating electrical connections in demanding environments. They electrically connect components to the ground. Once in place, they tend to:

- Stabilize the circuit;

- Reduce electromagnetic interference (EMI);

- Prevent static electricity buildup.

These are small mechanical parts (only a few millimeters) designed to easily fit various printed circuit board designs. They are reliable and capable of withstanding very harsh environments (high humidity levels, temperature variations, constant vibrations, etc.).

Spring finger contacts SMD incorporate a spring mechanism that ensures a constant and stable electrical connection, even in the presence of motion. They offer an economical solution to establish reliable ground connections without requiring complex or expensive procedures.

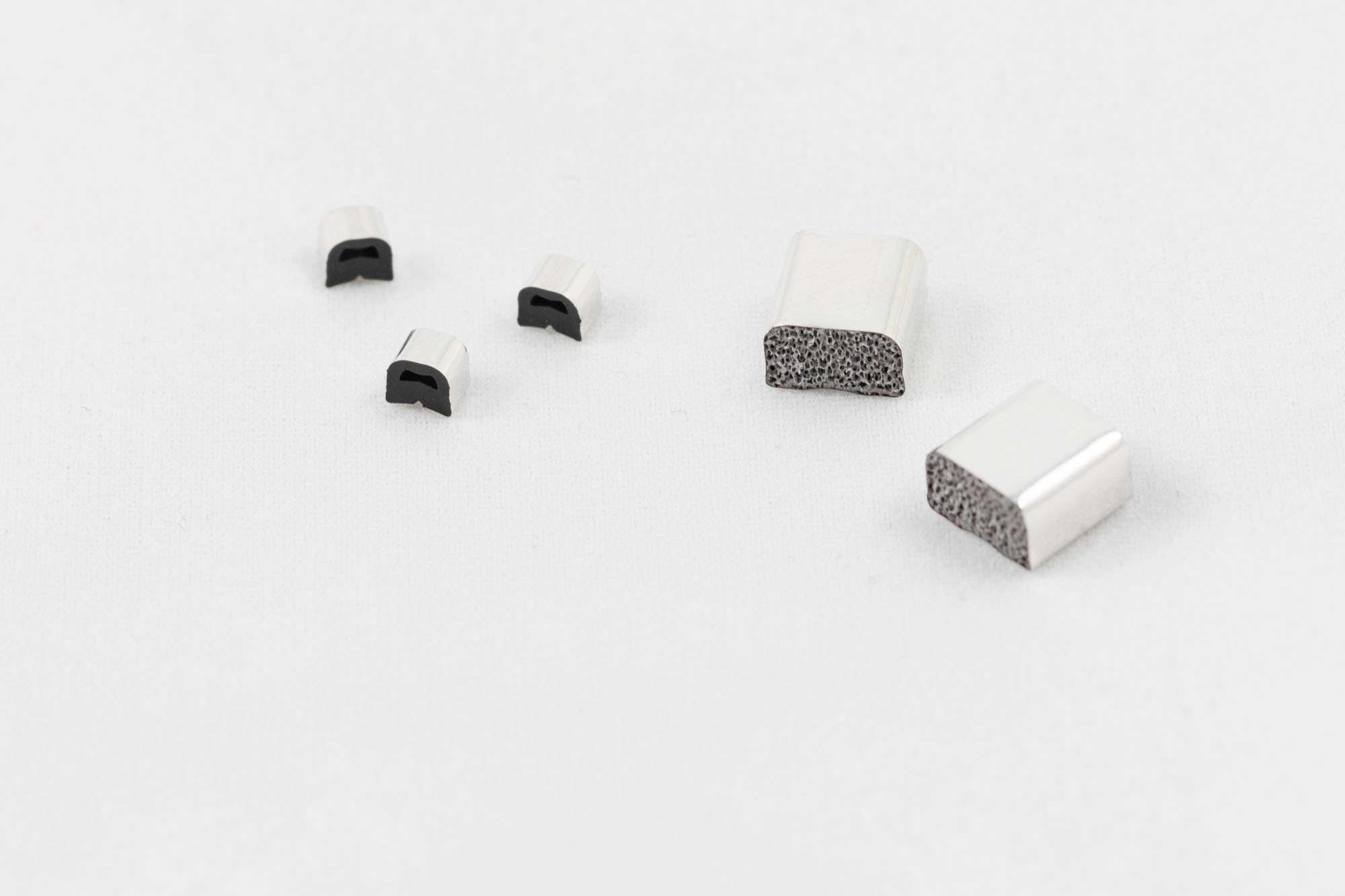

Characteristics of Soft SMD Contact Pads

Soft SMD contact pads are flexible electrical elements consisting of a metallic strip and a foam or silicone body. This composition gives them great flexibility and significant compression capability.

Indeed, Soft SMD contact pads can be compressed up to 90% of their height, significantly reducing mechanical stress on the PCB (printed circuit board). This makes them particularly suitable for applications requiring a reliable connection in confined spaces or environments where components may be subject to mechanical stress.

Applications for Spring Finger Contacts SMD

Spring finger contacts SMD are extremely versatile. They find applications in a multitude of fields requiring reliable electrical connections, particularly where conditions can be demanding. These parts are designed for compression ranging from 5% to 40% in most applications.

They can be used to connect cell phone antennas, GPS, and automotive antennas for stable and reliable signal transmission. They also facilitate the connection between PCBs or between a PCB and a chassis by preventing electromagnetic interference (EMI) and static electricity.

Finally, they can be used in electrical devices such as:

- Automotive assemby (infotainment systems)

- Electric bicycles;

- Household appliances;

- Cameras;

- Cell phones, etc.

Given their resistance to vibrations, they are also perfect for automotive applications, military equipment, or aeronautics.

Applications for Soft SMD Contact Pads

Soft SMD contact pads, especially those made of silicone, are used in a wide range of applications due to their flexibility. They are particularly effective for:

- Grounding connections;

- Minimizing EMI noise;

- Reducing static electricity in electronic assemblies.

They can be used in the industrial and automotive sectors. In the automotive sector, Soft SMD contact pads ensure the stable operation of the vehicle while minimizing electromagnetic interference.

They can be integrated into vehicles, at dashboards, navigation systems, or engine control systems to ensure stable operation and minimize electromagnetic interference. Lastly, Soft SMD contact pads also find applications in industrial equipment. In this case, they help maintain stable performance of electronic systems under potentially tough conditions, such as high temperatures or environments with strong vibrations.

Soft SMD Contact Pads or Spring Finger Contacts SMD: Which to Choose?

The choice between Soft SMD contact pads and Spring finger contacts SMD depends on several factors:

- Your budget;

- The design constraints of the project;

- Your expectations regarding electrical performance.

That being said, if your application requires high compressibility to minimize space or mechanical stress on components, Soft SMD contact pads are preferable. Their ability to be compressed up to 90% of their original height allows for easy integration in confined spaces. They usually offer a more competitive cost, which is also an advantage. Similarly, if your main concern is reducing electromagnetic interference, silicone Soft SMD contact pads are an excellent option.

In contrast, if your application is subject to extreme conditions (vibrations, shocks, humidity, temperature variations, etc.), it is better to opt for Spring finger contacts SMD that offer superior reliability. These elements are also ideal for establishing low-voltage electrical connections requiring great reliability and stability.

Lastly, due to their ability to maintain constant pressure and provide excellent conductivity, they are useful in a variety of applications:

- Antenna connections;

- Grounding connections;

- Connections between PCBs (or between PCB and chassis).

In any case, both types of components are supplied in reels for automatic placement.

Ultimately, there is no single answer to this question; the choice between Soft SMD contact pads and Spring finger contacts SMD depends on the specific requirements of each application.

Still having trouble deciding after reading our article? Do not hesitate to contact our teams who will guide and help you choose the best option for your project’s needs.