Ultrasoft thermal interfaces are essential for heat transfer between electronic components and their heat sinks, bridging gaps and irregularities on surfaces. They ensure perfect contact for optimal thermal dissipation, keeping electronic components within operational temperature limits. However, dissipating heat from electronic components isn’t always straightforward, given the significant gaps, tolerances to compensate for, or even low compression forces. To mitigate these challenges, there is a solution: utilizing ultrasoft thermal interfaces (TIM). In this article, we will cover everything you need to know about this topic.

Thermal Interfaces: What Are We Talking About?

Thermal interfaces are crucial for managing heat transfer in electronic applications, maintaining the performance and reliability of components.

Essentially, a thermal interface is a material placed between two surfaces to facilitate heat transfer from one surface to another. This layer is often necessary because the surfaces in contact typically have microscopic imperfections, which limit the effective contact area and, consequently, the thermal transfer capacity. Thermal interfaces fill these imperfections, thereby improving thermal conductivity between surfaces.

Thermal interfaces are predominantly made of silicone, making them electrically non-conductive but thermally conductive.

Using thermal interfaces ultimately reduces thermal resistance at the interface between the electronic component and its heat sink. This results in better thermal performance and greater system reliability.

What Makes it Ultrasoft?

Ultrasoft thermal interfaces belong to a specific category featuring very low hardness yet high conformability.

These materials are designed to easily deform under low pressure, optimally filling micro-roughness and gaps between contact surfaces. They also compensate for significant gaps between components of different heights on the same PCB, while minimizing compression forces and, thus, the risk of component damage or PCB warping.

This property further minimizes thermal resistance at the interface. By deforming to encompass electronic components, it ensures better contact and hence better thermal conductivity.

Ultrasoft thermal interfaces are particularly useful:

- In applications where contact surfaces have significant irregularities (height differences between components on the same PCB);

- Or when components cannot be subjected to high mounting pressures.

Advantages of Using Ultrasoft Thermal Interface (TIM)

Ultrasoft thermal interfaces provide several significant advantages. Their high conformability efficiently fills gaps and surface irregularities between components and heat sinks, reducing thermal resistance and improving heat transfer.

Thanks to their flexibility, these interfaces require only low pressure to establish effective contact. This is particularly beneficial for sensitive components or assemblies where applying high pressure is impractical.

Moreover, they adapt to various surface topographies, making them useful for a wide range of applications where surfaces are not perfectly flat or smooth.

Their soft and malleable nature makes them easy to handle and apply onto components.

Additionally, these interfaces are designed to maintain their mechanical and thermal properties over a long duration, even in high-temperature conditions.

In summary, using ultrasoft thermal interfaces can significantly improve heat dissipation efficiency in electronic systems, offering flexibility and reliability in design and assembly.

Ultrasoft Thermal Interfaces from Compelma

At Compelma, we understand that dissipating heat from electronic components is often a complex challenge. It is often necessary to:

- Compensate tolerances;

- Manage low compression forces;

- Fill significant gaps;

- Account for parts subjected to shocks.

Therefore, we have developed a new range of soft and ultrasoft thermal interfaces. With ultrasoft thermal interfaces, there is no need to adapt your design to thermal dissipation constraints; our interface adapts to your needs. We have in-house cutting machines capable of producing custom-designed thermal interfaces, ready to integrate into your components.

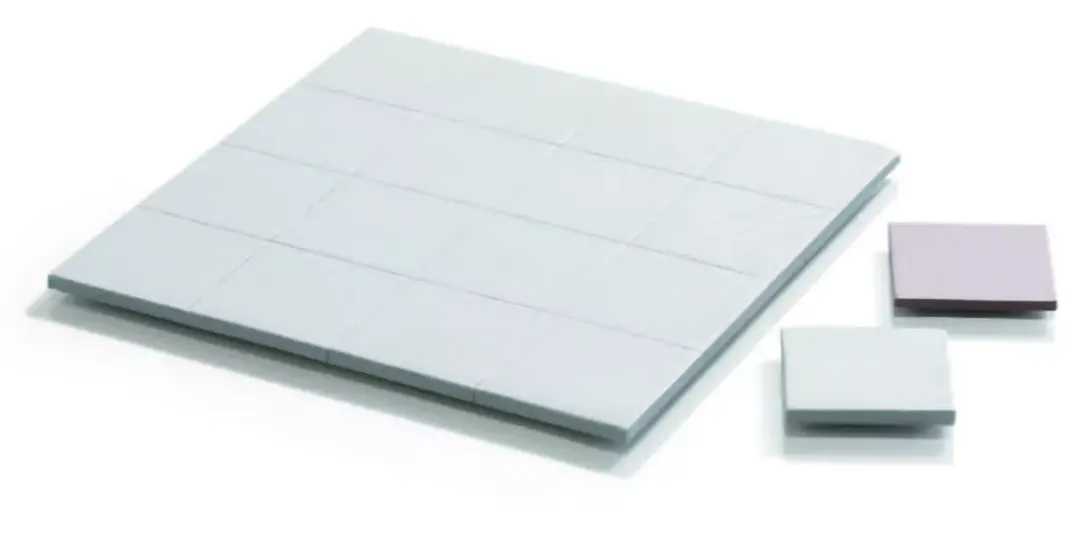

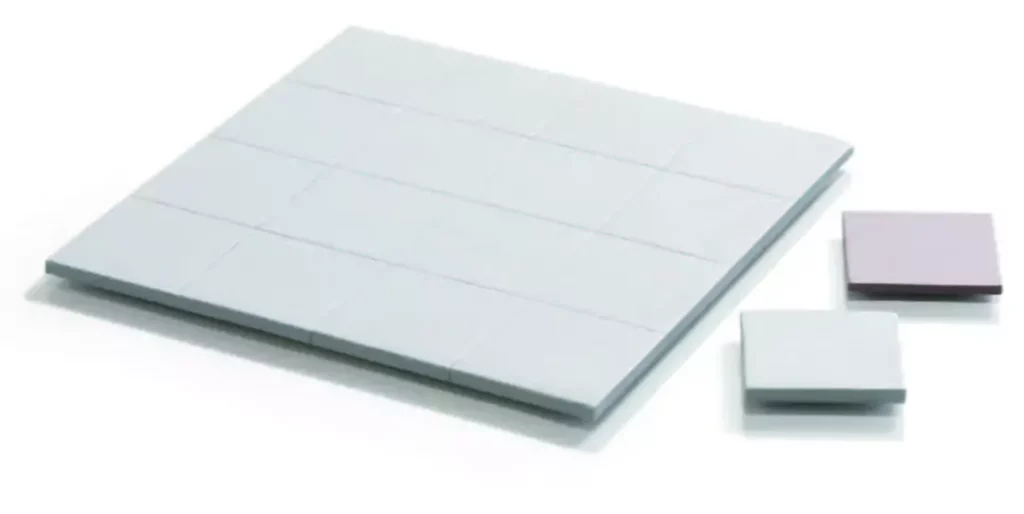

Our thermal dissipation interfaces are available as sheets or pre-cut parts with different surface finishes to fit any industrial process.

With our technological expertise, we also offer custom ultrasoft thermal interface solutions. Our production unit in France can produce your prototypes and small series in very short lead times. We can also supply these parts in large volumes, if necessary.

We deliver both domestically and internationally. With our numerous production sites worldwide, we ensure optimized merchandise flow, regardless of your location.

Our commitment is to provide thermal interfaces that not only meet high technical standards but also integrate perfectly into your manufacturing process. Our products will help you maximize the performance and reliability of your electronic components.

Do you have any more questions about ultrasoft thermal interfaces? Are you convinced and want to get a quote? Don’t hesitate to contact us.